- Plastic Extruder Machine

- Plastic Extruder

- Solid Pipe Extrusion Line

- Composite Pipe Extrusion Line

- PPR-Plastic Aluminums Stable Production Line

- Overlap Welding Aluminum-Plastic Composite Pipe Extrusion Line

- Silicon-Core Compounding Pipe Production Line

- PVC Fiber Reinforce Braided Pipe Extrusion Line

- PVC Steel Wire Reinforce Hose Production Line

- PVC Plastic Rib Spiral Reinforced Hose Production Line

- PVC Screw Thread Colored Plastic Pipe (Shower Pipe)Production Line

- Inner Inlay Flat Drip Irrigation Pipe

- Labyrinth Pipe Irrigation Belt

- Inner inlay flat style drip irrigation pipe

- Corrugated Pipe Extrusion Line

- Large Diameter Hollow-wall Twisted Pipe Extrusion Line

- Plastic Profile Extrusion Line

- Plastic Sheet & Board Extrusion Line

- PVC Free Foamed Sheet And Decorative Sheet Extrusion Line

- PP,PC Plastic Hollow Board Extrusion Line

- PP,PC And PVC Single/Multi-Layer Corrugate Sheet Extrusion Line

- ABS,HIPS,PMMA, Single Or Multi-Layer Plate Extrusion Line

- PVC Skinning/Semi-Skinning Foaming Board Extrusion Line

- Plastic Sheet Production Line

- Plastic Thermoforming Machine

- Medical High Precision Extrusion Line

- Foamed Plastic Sheet & Film Extrusion Line

- Plastic Pelletizing & Recycling Line

- PVC Hot-Cutting Pelletizing Line

- PE/PP Film Washing & Cleaning Plant

- PE/PP Recycling & Pelletizing Production Line

- PET Bottle Fakes Washing & Cleaning Plant

- PET Pelletizing Line

- Two-Stage Compounding Extruder Pelletizing System

- Twin screw pelletizing line

- Double-ranks recycling & granulating line

- Economic bottle flakes washing

- Auxiliary Equipment

- SHR Series High Speed Heating Mixer

- SRLZ Series Heating And Cooling Mixer Unit

- SPL Series Heating And Cooling Mixer Unit

- Automic Belling Machine

- Semi-Automic Belling Machine(50-250mm R Type And U Type)

- Manual Pipes Fitting Belling Machine(50-160mm Blow Type)

- SWP400-600 Series Plastic Breaker

- SML Series High Speed Whirl Pool Multifunction Mill

- Auxiliary Equipment

- Chiller

- washing machine pipe/corrugated basin pipe blowing machine

- Plastic Injection Machine

- Silicon Injection Machine

- Rubber & EVA Machine

- Blowing Machine

- Aluminum Machine

- Packing Machine

|

Add: No. 910 Dushi Renhe Building, No. 58 Qi Zha Street Haishu Zone, Ningbo, China |

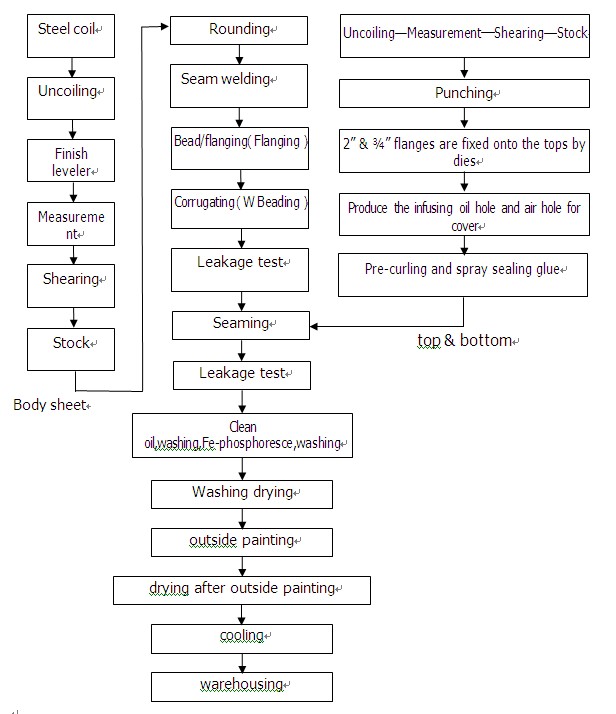

| 205L Steel-Drum Production Line (Output is 3-4 drums/min) |

|

| Technological process: Shearing section drum/barrel body section top & bottom lids section |

|

| 1、 The production line of de-coil, level, measurement cutting |

|

| 2、 Steel drum body production line |

|

| 3、205L steel drums production line rear treatment (wash, drying, painting system, etc.) |

|